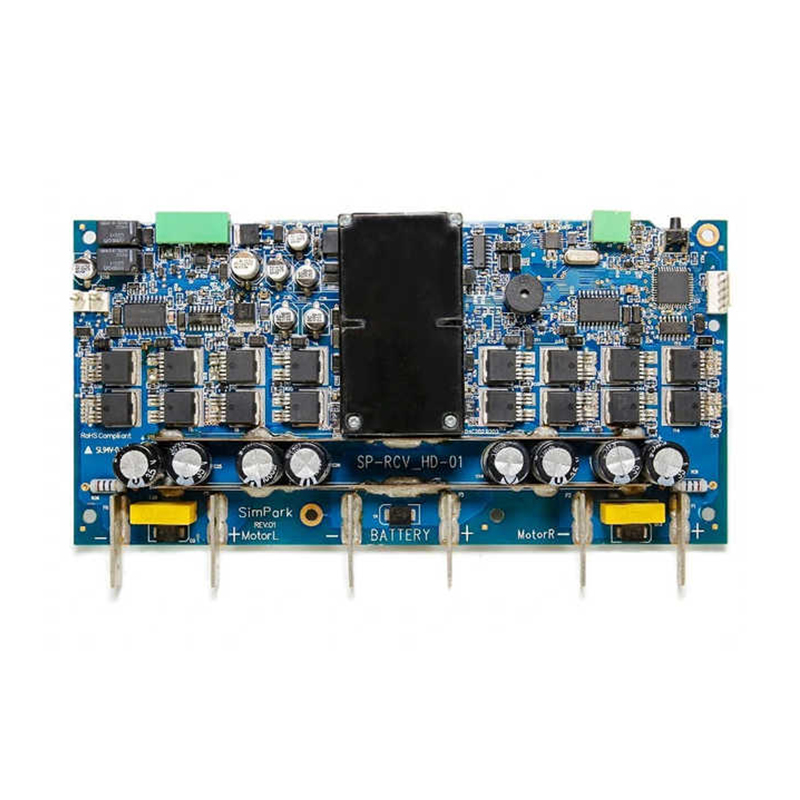

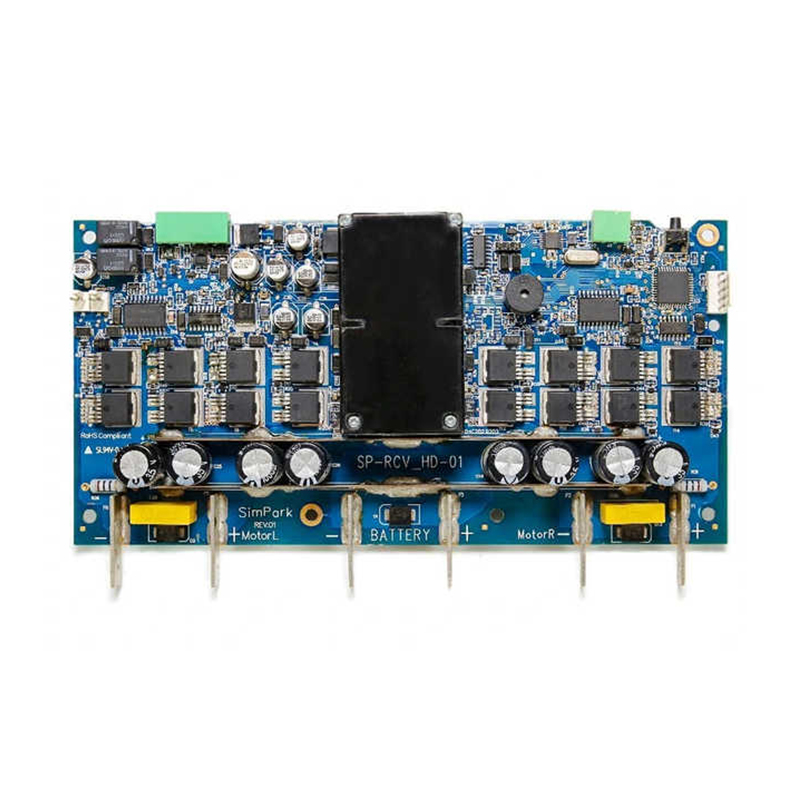

Manufacturer communication Server PCB Board PCB Assembly Manufacture

Products feature

● Material: Fr-4

● Layer Count: 6 layers

● PCB Thickness: 1.2mm

● Min. Trace / Space Outer: 0.102mm/0.1mm

● Min. Drilled Hole: 0.1mm

● Via Process: Tenting Vias

● Surface Finish: ENIG

PCB structure characteristics

1. Circuit and pattern (Pattern): The circuit is used as a tool for conducting between components. In the design, a large copper surface will be designed as a grounding and power supply layer. Lines and drawings are made at the same time.

2. Hole (Throughole/via): The through hole can make the lines of more than two levels conduct each other, the larger through hole is used as a component plug-in, and the non-conductive hole (nPTH) is usually used as the surface Mounting and positioning, used for fixing screws during assembly.

3. Solderresistant ink (Solderresistant/SolderMask): Not all copper surfaces have to eat tin parts, so the non-tin-eaten area will be printed with a layer of material (usually epoxy resin) that isolates the copper surface from eating tin to avoid non-soldering. There is a short circuit between the tinned lines. According to different processes, it is divided into green oil, red oil and blue oil.

4. Dielectric layer (Dielectric): It is used to maintain the insulation between lines and layers, commonly known as the substrate.

PCBA technical Capacity

| SMT | Position accuracy:20 um |

| Components size:0.4×0.2mm(01005) —130×79mm,Flip-CHIP,QFP,BGA,POP | |

| Max. component height::25mm | |

| Max. PCB size:680×500mm | |

| Min. PCB size:no limited | |

| PCB thickness:0.3 to 6mm | |

| PCB weight:3KG | |

| Wave-Solder | Max. PCB width:450mm |

| Min. PCB width: no limited | |

| Component height:Top 120mm/Bot 15mm | |

| Sweat-Solder | Metal type :part, whole, inlay, sidestep |

| Metal material:Copper , Aluminum | |

| Surface Finish:plating Au, plating sliver , plating Sn | |

| Air bladder rate:less than 20% | |

| Press-fit | Press range:0-50KN |

| Max. PCB size:800X600mm | |

| Testing | ICT,Probe flying,burn-in,function test,temperature cycling |

Manufacturer Communication Server PCB Board PCB Assembly Manufacturer has state-of-the-art designs that ensure seamless communication and connectivity. The product is equipped with state-of-the-art hardware components, including high-performance processors, memory modules and network interfaces. Our team of experts have carefully crafted this PCB board to meet the highest industry standards and deliver superior performance.

The PCB assembly manufacturing process involves several key steps, including component sourcing, surface mounting, and soldering. Our skilled technicians and advanced machinery ensure the precise assembly of each PCB board, ensuring reliable and efficient operation. We take meticulous quality control measures to minimize the risk of defects and ensure our customers receive only the best products.

One of the outstanding features of our Manufacturer Communication Server PCB Board PCB Assembly Manufacturer is its excellent scalability. The product features a modular design that can be easily customized and expanded. It can adapt to various communication server needs and become a universal solution for different industries. Additionally, our PCB boards are designed to be easily integrated into existing systems, minimizing downtime and maximizing productivity.

Our commitment to producing environmentally friendly products is reflected in Manufacturer Communication Server PCB Board PCB Assembly Manufacturing. We prioritize energy efficiency and sustainability throughout our manufacturing processes, ensuring our products comply with international environmental standards. By choosing our PCB boards, customers not only benefit from advanced communication capabilities but also contribute to a greener future.

We understand the importance of reliability and durability in the communications server industry. That is why our Manufacturer Communication Server PCB Board PCB Assembly manufacturing facility undergoes stringent testing procedures to ensure its sturdiness and longevity. It can withstand harsh operating conditions, including temperature changes, vibration and electrical fluctuations. Our products are built to last, minimizing maintenance costs and maximizing uptime.

Manufacturer Communication Server PCB Board PCB Assembly Manufacturing is a game-changing solution designed to take communication servers to new heights. Offering superior performance, scalability, sustainability and durability, this product is the right choice for industries looking for reliable and efficient connectivity. Trust our expertise and choose our products to unlock seamless and enhanced communication capabilities in your business operations.