PCB assembly is a critical process in electronic device manufacturing. Proper assembly of printed circuit boards (PCBs) ensures the functionality and reliability of electronic devices. In this blog post, we’ll delve into the basics of PCB assembly, discuss its importance, and highlight the benefits of professional assembly services.

Learn about PCB assembly.

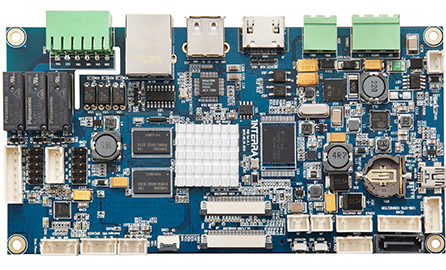

PCB assembly involves the process of mounting electronic components onto a bare PCB. It includes two main methods: through-hole technology (THT) and surface mount technology (SMT). Through-hole technology involves inserting leads into holes in a PCB, while surface-mount technology involves soldering components directly to the surface of the circuit board.

The importance of proper PCB assembly.

1. Functionality: A well-assembled PCB ensures the normal operation of electronic equipment. Poor assembly can cause PCB failure, short circuits, or even complete failure, resulting in expensive repairs or replacements.

2. Reliability: High-quality assembly ensures the reliability of electronic equipment and reduces the risk of failure during critical operations. Proper soldering techniques can prevent poor connections and ensure stability, avoiding intermittent problems.

3. Miniaturization: PCBs are becoming smaller and more complex, and manual assembly is no longer feasible with advanced technology. Professional PCB assembly services use automated equipment such as pick-and-place machines to accurately place components, even on tiny and dense circuit boards.

4. Time Efficiency: Professional assembly services have the expertise, experience, and specialized equipment to streamline the assembly process, thereby reducing production time. This ensures quick turnaround and enables manufacturers to meet market demands and deadlines efficiently.

The advantages of professional PCB assembly services.

1. Professional knowledge: Professional assembly services employ skilled technicians who are proficient in PCB assembly technology, understand the latest industry standards, and understand various component types. Their expertise ensures accurate placement, correct soldering, and correct testing of assembled PCBs.

2. Equipment: Professional assembly services invest in state-of-the-art equipment such as stencil printers, soldering furnaces, and automatic assembly machines. These advanced tools ensure precise component placement, uniform soldering, and thorough inspection to produce high-quality PCBs.

3. Quality control: Professional assembly services adhere to strict quality control measures to ensure the reliability and functionality of assembled PCBs. They follow industry standards, conduct comprehensive inspections, and use advanced testing methods such as Automated Optical Inspection (AOI) to detect any faults and correct them promptly.

4. Cost-Effectiveness: While outsourcing PCB assembly may seem costly, it proves to be a cost-effective solution in the long run. Professional assembly services eliminate the need for expensive equipment, training and labor. Additionally, reduced PCB defects and high-quality output contribute to overall cost savings.

To sum up, PCB assembly plays a pivotal role in the manufacturing process of electronic devices. Choosing professional assembly services ensures functionality, reliability and cost-effectiveness. Working with experts in the field saves time, eliminates errors, and guarantees high-quality PCBs, ultimately benefiting manufacturers and end-users. So, if you need PCB assembly, consider the benefits and expertise of professional services for the best results.

Post time: Sep-06-2023