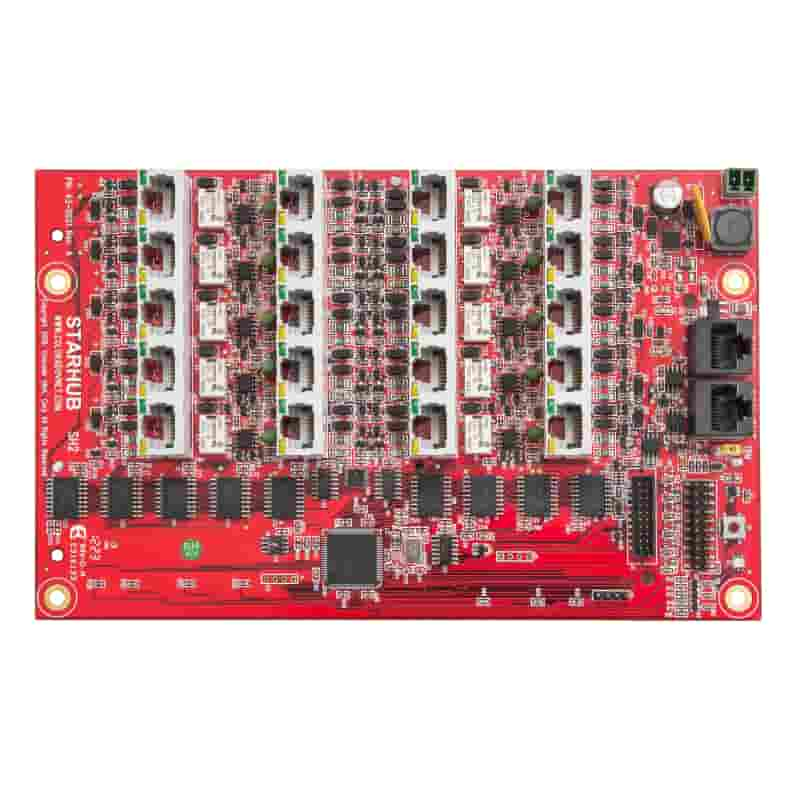

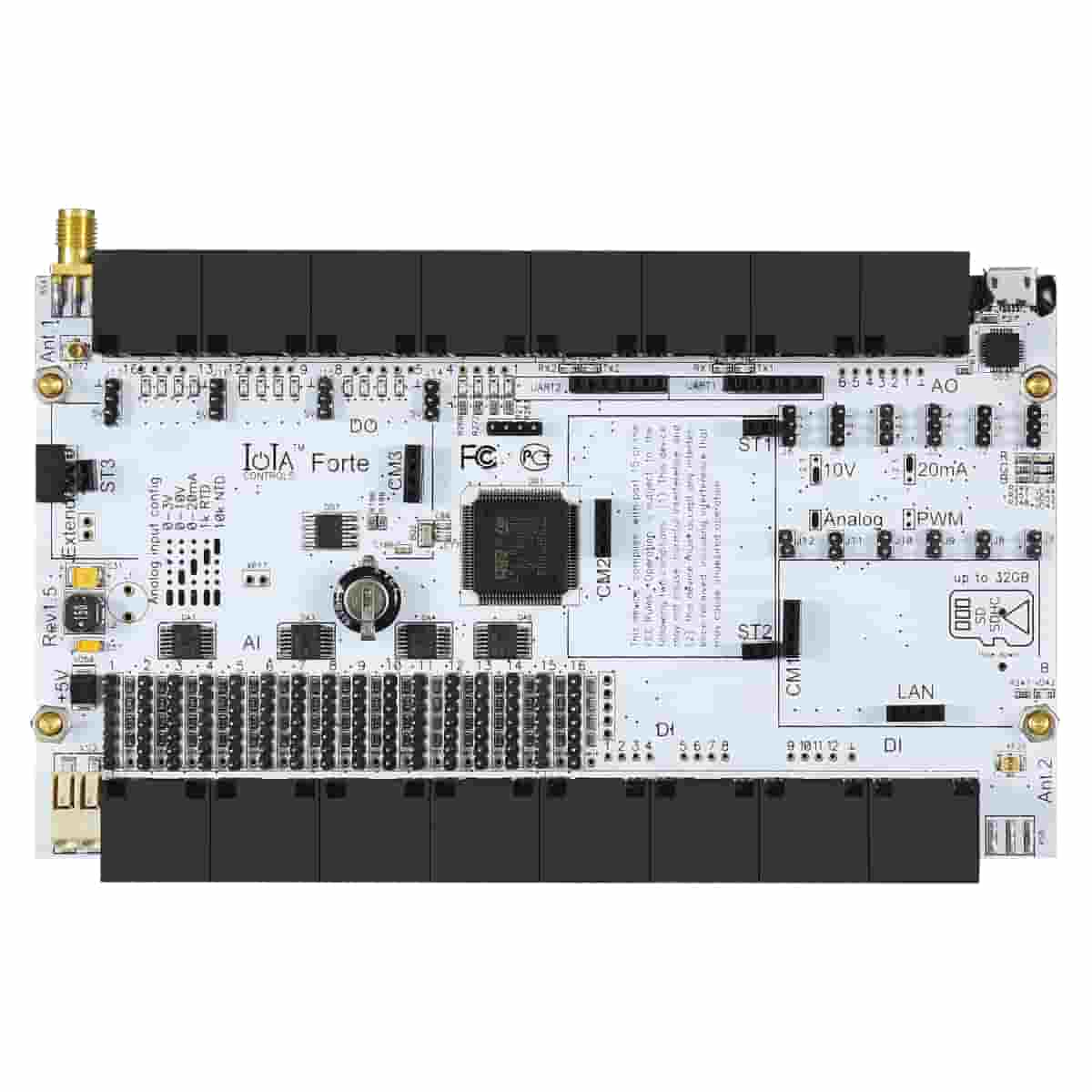

One stop electronic Server PCBA board manufacturer

Products feature

● Material: Fr-4

● Layer Count: 6 layers

● PCB Thickness: 1.2mm

● Min. Trace / Space Outer: 0.102mm/0.1mm

● Min. Drilled Hole: 0.1mm

● Via Process: Tenting Vias

● Surface Finish: ENIG

PCB structure characteristics

1. Circuit and pattern (Pattern): The circuit is used as a tool for conducting between components. In the design, a large copper surface will be designed as a grounding and power supply layer. Lines and drawings are made at the same time.

2. Hole (Throughole/via): The through hole can make the lines of more than two levels conduct each other, the larger through hole is used as a component plug-in, and the non-conductive hole (nPTH) is usually used as the surface Mounting and positioning, used for fixing screws during assembly.

3. Solderresistant ink (Solderresistant/SolderMask): Not all copper surfaces have to eat tin parts, so the non-tin-eaten area will be printed with a layer of material (usually epoxy resin) that isolates the copper surface from eating tin to avoid non-soldering. There is a short circuit between the tinned lines. According to different processes, it is divided into green oil, red oil and blue oil.

4. Dielectric layer (Dielectric): It is used to maintain the insulation between lines and layers, commonly known as the substrate.

PCBA technical Capacity

| SMT | Position accuracy:20 um |

| Components size:0.4×0.2mm(01005) —130×79mm,Flip-CHIP,QFP,BGA,POP | |

| Max. component height::25mm | |

| Max. PCB size:680×500mm | |

| Min. PCB size:no limited | |

| PCB thickness:0.3 to 6mm | |

| PCB weight:3KG | |

| Wave-Solder | Max. PCB width:450mm |

| Min. PCB width: no limited | |

| Component height:Top 120mm/Bot 15mm | |

| Sweat-Solder | Metal type :part, whole, inlay, sidestep |

| Metal material:Copper , Aluminum | |

| Surface Finish:plating Au, plating sliver , plating Sn | |

| Air bladder rate:less than 20% | |

| Press-fit | Press range:0-50KN |

| Max. PCB size:800X600mm | |

| Testing | ICT,Probe flying,burn-in,function test,temperature cycling |